4.24. DESIGN OF A CHEMICAL REACTOR

A simulation model with Vensim

One distinctive characteristic of industrial processes is its complex structure, generally constructed by many phases; each one consisting of numerous sub components. Its mathematical description generates equations ranging from simple equations to very complicated ones.

This is added to the lack of an exhaustive knowledge of the characteristics of the sub components and the elevated grade of interrelation between the variables, generator of non lineal results that complicate the exact resolution of the equations.

In this way, the design of new plants and the optimisation of the existing ones, two inherent tasks in the activity of engineers of process and project, usually requires intuitive criteria. Neither for economic reasons or security is it possible to carry out these excessive laboratory simulations or experiment with existing plants.

As a result, the systematic analysis and the creation of dynamic simulation models appear to be a very attractive solution to the problem.

Physiochemical characteristics of the process considered.

The present model simulates the behaviour of a discontinued reactor, perfectly mixed, of a constant volume, with a system of temperature regulation using an interior coil where a reaction in the gaseous phase of the first order is completed.

In the figure a simplified scheme of the reactor is shown, with the agitator that ensures it is mixed perfectly and the cooling coil, around which a cooling current circulates to Tm with enough flow in order not to experiment a significant change in temperature.

The reaction of conversion from A in products B and C is exothermic, during its development it generates a quantity of heat that can be calculated starting from the heat of its reaction, HR. In this way, not applying a cooling system, the temperature of the reactor will increase constantly. There are also other factors that should be considered.

1) The elevation of the temperature in the reactor is related to the global calorific capacity of the mix contained and this continues to vary with the advance of the reaction since A is substituted by B and C. Where the n¡ are the mols of each component to a time t, and the C¡ are the respective calorific capacities, considered constants for which ever value of the Temperature. Given the certain stequiometry of reaction, the expression can be simplified expressing it only depending on NA.

2) The constant K of the reaction depends on the temperature and in another way, the generation of heat of the number of moles of A present in the reactor to a time t, as it can be seen in the energy balance equation. This generates a double link between the equations representative of the process and to introduce difficulties for the solution.

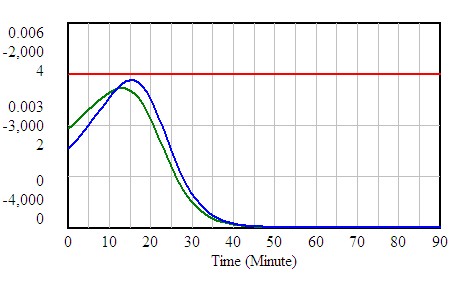

For the construction of a dynamic simulation model, two levels have been considered: in one the disappearance of A is produced by reaction, in the other the accumulation of heat by reaction and its dissipation through refrigeration that is measured using the temperature. The symbols of the equations have been conserved, the usual equations in the field of chemical engineering.

The model reproduces the behaviour obtained using the application of the most complex analogical models like those of Himmelblau and Bischoff that are described in "Analysis and simulation of processes" (Ed. Reverté. 1976). This allows us to see clearly the behaviour of this idea reactor under different conditions of operation, given that it is possible to change the temperature of the refrigerator, the area of transference of heat, the initial temperature of the process and the global coefficient of the transference of heat.

One distinctive characteristic of industrial processes is its complex structure, generally constructed by many phases; each one consisting of numerous sub components. Its mathematical description generates equations ranging from simple equations to very complicated ones.

This is added to the lack of an exhaustive knowledge of the characteristics of the sub components and the elevated grade of interrelation between the variables, generator of non lineal results that complicate the exact resolution of the equations.

In this way, the design of new plants and the optimisation of the existing ones, two inherent tasks in the activity of engineers of process and project, usually requires intuitive criteria. Neither for economic reasons or security is it possible to carry out these excessive laboratory simulations or experiment with existing plants.

As a result, the systematic analysis and the creation of dynamic simulation models appear to be a very attractive solution to the problem.

Physiochemical characteristics of the process considered.

The present model simulates the behaviour of a discontinued reactor, perfectly mixed, of a constant volume, with a system of temperature regulation using an interior coil where a reaction in the gaseous phase of the first order is completed.

In the figure a simplified scheme of the reactor is shown, with the agitator that ensures it is mixed perfectly and the cooling coil, around which a cooling current circulates to Tm with enough flow in order not to experiment a significant change in temperature.

The reaction of conversion from A in products B and C is exothermic, during its development it generates a quantity of heat that can be calculated starting from the heat of its reaction, HR. In this way, not applying a cooling system, the temperature of the reactor will increase constantly. There are also other factors that should be considered.

1) The elevation of the temperature in the reactor is related to the global calorific capacity of the mix contained and this continues to vary with the advance of the reaction since A is substituted by B and C. Where the n¡ are the mols of each component to a time t, and the C¡ are the respective calorific capacities, considered constants for which ever value of the Temperature. Given the certain stequiometry of reaction, the expression can be simplified expressing it only depending on NA.

2) The constant K of the reaction depends on the temperature and in another way, the generation of heat of the number of moles of A present in the reactor to a time t, as it can be seen in the energy balance equation. This generates a double link between the equations representative of the process and to introduce difficulties for the solution.

For the construction of a dynamic simulation model, two levels have been considered: in one the disappearance of A is produced by reaction, in the other the accumulation of heat by reaction and its dissipation through refrigeration that is measured using the temperature. The symbols of the equations have been conserved, the usual equations in the field of chemical engineering.

The model reproduces the behaviour obtained using the application of the most complex analogical models like those of Himmelblau and Bischoff that are described in "Analysis and simulation of processes" (Ed. Reverté. 1976). This allows us to see clearly the behaviour of this idea reactor under different conditions of operation, given that it is possible to change the temperature of the refrigerator, the area of transference of heat, the initial temperature of the process and the global coefficient of the transference of heat.

|

See the book

See the book

See the book

See the book