4.9. MANAGEMENT OF PRODUCTION AND INVENTORY

A simulation model with Vensim

A manufacturing firm has experienced chronic instability in its inventory level and production rate. Your discussions with management and workers on the factory floor have revealed the following information:

1. The firm supplies its customers from a stock of finished inventory, which is generally sufficient to meet orders as they are received.

2. Desired production is determined by anticipated (forecasted) shipments, modified by a correction to maintain inventory at the desired level.

3. The firm forecasts shipments by averaging past orders over an eight-week period as a way of smoothing out any noise or lumpiness in demand.

4. The firm tries to correct discrepancies between desired and actual inventory in eight weeks.

5. Desired inventory is four weeks' worth of anticipated shipments.

The firm's actual production rate is assumed to equal desired production. The initial value for inventory is assumed to be equal to desired inventory, and the initial value of the average shipment rate is assumed to be the actual shipment rate. As a result, the model will begin in an initial equilibrium regardless of the initial customer order rate.

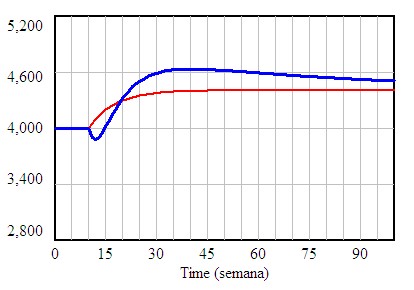

In this model customer orders will equal a constant Order Rate (of 1,000 units/week) until the period 10, when orders step up by 10%, and then remain at the higher rate.

Nothing that the current model assumes actual production equals desired production, you return to the company to check on the validity of that assumption. Further discussions reveal that while the firm has ample physical plant and equipment, labor cannot be hired and trained instantaneously. In fact, it takes approximately 24 weeks to advertise for, hire, and train new workers. The firm has a no-layoff policy, and workers stay with the firm an average of 50 weeks (one year).

The firm's hiring policy is to replace those workers who quit, modified by a correction to bring the actual workforce into balance with the desired workforce. Because workers must give two weeks notice, there is no significant delay between quits and replacement hiring. Because of the delays in hiring new people, it takes 24 weeks to make corrections to the workforce. The desired workforce is determined by desired production and average productivity, which is equal to 20 units per worker per week and is quite constant over time. Finally, union rules prevent the use of overtime or undertime.

The firm wants to know whether they should press for the right to schedule overtime / undertime in upcoming contract negotiations with the union.

The normal workweek is 40 hours. Preliminary negotiations with the union reveal that they would be willing to allow a minimum of 35 hours per week and a maximum of 50 hours, at time-and-a-half, in return for increase in employee benefits and pension fund contributions. You agree to evaluate the benefits of overtime / undertime with the model so management knows what overtime is worth in improved stability.

A manufacturing firm has experienced chronic instability in its inventory level and production rate. Your discussions with management and workers on the factory floor have revealed the following information:

1. The firm supplies its customers from a stock of finished inventory, which is generally sufficient to meet orders as they are received.

2. Desired production is determined by anticipated (forecasted) shipments, modified by a correction to maintain inventory at the desired level.

3. The firm forecasts shipments by averaging past orders over an eight-week period as a way of smoothing out any noise or lumpiness in demand.

4. The firm tries to correct discrepancies between desired and actual inventory in eight weeks.

5. Desired inventory is four weeks' worth of anticipated shipments.

The firm's actual production rate is assumed to equal desired production. The initial value for inventory is assumed to be equal to desired inventory, and the initial value of the average shipment rate is assumed to be the actual shipment rate. As a result, the model will begin in an initial equilibrium regardless of the initial customer order rate.

In this model customer orders will equal a constant Order Rate (of 1,000 units/week) until the period 10, when orders step up by 10%, and then remain at the higher rate.

Nothing that the current model assumes actual production equals desired production, you return to the company to check on the validity of that assumption. Further discussions reveal that while the firm has ample physical plant and equipment, labor cannot be hired and trained instantaneously. In fact, it takes approximately 24 weeks to advertise for, hire, and train new workers. The firm has a no-layoff policy, and workers stay with the firm an average of 50 weeks (one year).

The firm's hiring policy is to replace those workers who quit, modified by a correction to bring the actual workforce into balance with the desired workforce. Because workers must give two weeks notice, there is no significant delay between quits and replacement hiring. Because of the delays in hiring new people, it takes 24 weeks to make corrections to the workforce. The desired workforce is determined by desired production and average productivity, which is equal to 20 units per worker per week and is quite constant over time. Finally, union rules prevent the use of overtime or undertime.

The firm wants to know whether they should press for the right to schedule overtime / undertime in upcoming contract negotiations with the union.

The normal workweek is 40 hours. Preliminary negotiations with the union reveal that they would be willing to allow a minimum of 35 hours per week and a maximum of 50 hours, at time-and-a-half, in return for increase in employee benefits and pension fund contributions. You agree to evaluate the benefits of overtime / undertime with the model so management knows what overtime is worth in improved stability.

|

See the book

See the book

See the book

See the book